-

Phone

15895689611

- Address

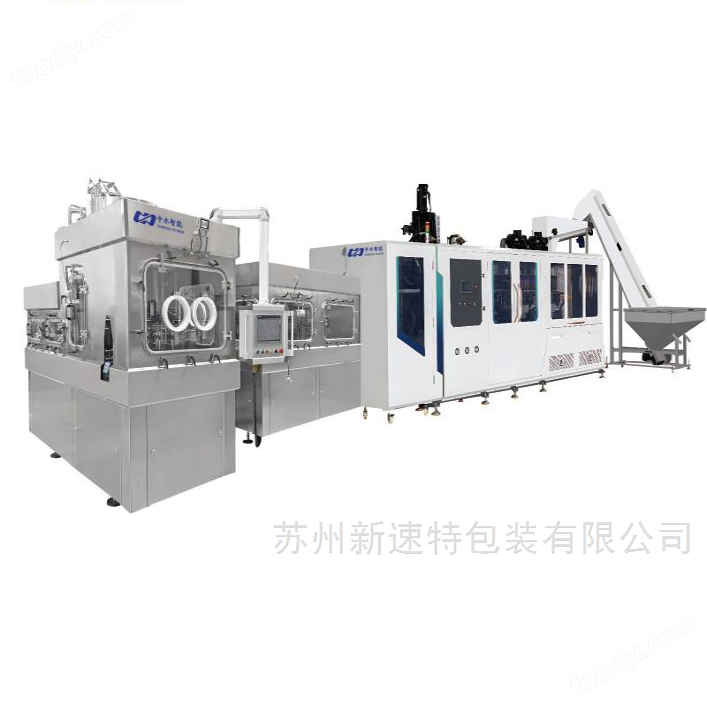

- Aseptic blowing, filling and spinning machine

- Carbonated beverage blowing, filling and spinning machine

- Bottled water blowing, filling and spinning machine

- homogenizer

- Hot filling, blowing, filling and spinning machine

- Non beverage blowing, filling and spinning machine

- Mixer

- Small bottle blowing machine

- Large packaging water blowing, filling and spinning machine

- Large bottle blowing machine

- Ultra clean blowing, filling and spinning machine

- Oversized bottle blowing machine

Suzhou Xinsute Packaging Co., Ltd

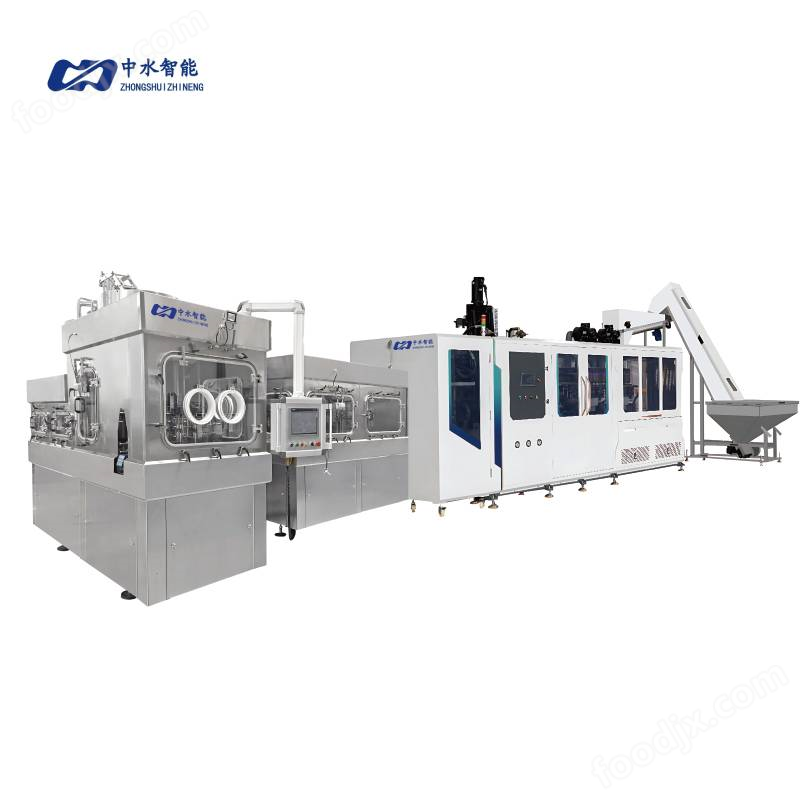

Ultra large bottle blowing machine system

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

superbigbottlebottle blowingmachineSystem:

PET rotary blow molding machine: good production efficiency, infinitely flexible configuration.

Intelligent blowing bottle for reclaimed waterCompared to domestic peers, energy consumption has been reduced by over 30% in electricity and over 10% in gas, with a total savings of 24000Blowing, irrigating, and spinningTaking the production line as an example, based on a daily production of 22 hours and an annual production of 280 days, using only electricity (blowing bottles and air compression) can save 550000 yuanRenminbi (RMB)/About a year.

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1. The manufacturer of the main components of the bottle blowing machine

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

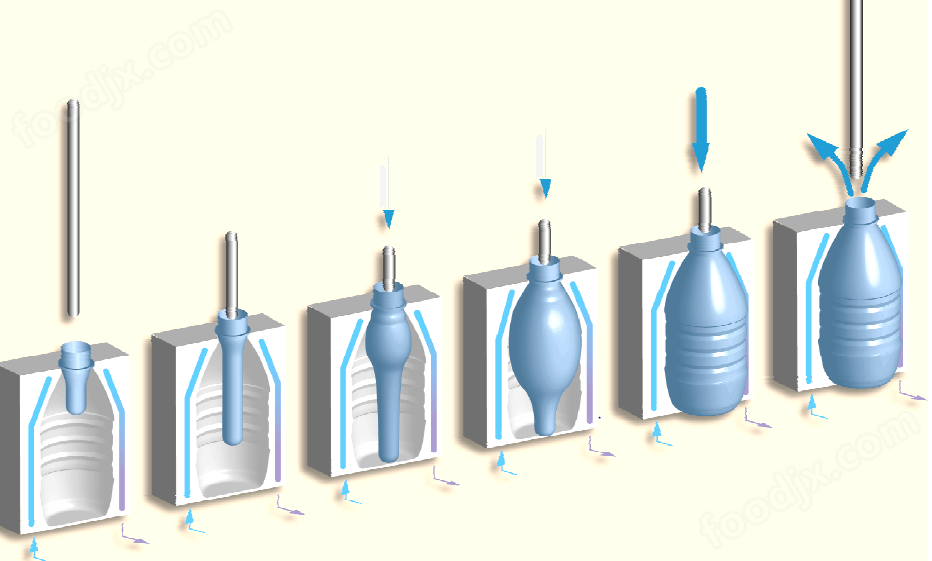

(Ultra large bottle blowing machine systemProcess flowchart 1. Hopper and feeding mechanism Storing a certain amount of bottle preforms through a hopper to ensure the continuity of production; The conveyor belt in the hopper lifts the bottle preforms to a higher levelblankThe organization arranges the preforms neatly in a row,Bottle preform cutting in sequenceThe track enters the heating furnace equipment of the bottle blowing machine. Equipment performance description: The bottle preforms are placed in the hopper and are monitored by the computer without the need for assistance. The amount of preforms can be automatically adjusted according to the production speed; According to different types of preforms, the output speed can be adjusted arbitrarily to ensure that the conveying volume of preforms is consistent with production; Rotating plastic conveyor belt and rotating drum conveyor ensure that bottle preforms are not damaged or contaminated during the transfer process. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

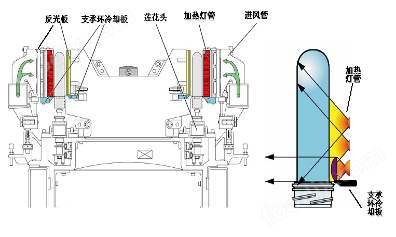

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Configure proportion adjustment pre blowing air, proportionValve brandGermanyMLSOr equivalent imported first-line brands, high-pressure gas sterile filtration system, sterile filter periodic sterilization system, filtration accuracy0.01umThe filter brand is Walker from the UK or an equivalent imported oneLine brand, no need for separate low-pressure intake. 1Configure quick mold locking/Gas delivery system, maximizing process range; 2Modular heating furnace design, ceramic reflector, furnace ventilation and airflow optimization system, minimizing heating energy consumption; Imported brands of heating lamps: Germany's Shangwei, Japan's Toshiba, or the United StatesGE 3Optimized heater group and temperature control system; The environmental requirements for the use of bottle blowing machines are above zero8-45degree 4Stable and uniform heating control, heating lamp tube can be turned on and the power can be adjusted; | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||