-

Phone

15895689611

- Address

- Aseptic blowing, filling and spinning machine

- Carbonated beverage blowing, filling and spinning machine

- Bottled water blowing, filling and spinning machine

- homogenizer

- Hot filling, blowing, filling and spinning machine

- Non beverage blowing, filling and spinning machine

- Mixer

- Small bottle blowing machine

- Large packaging water blowing, filling and spinning machine

- Large bottle blowing machine

- Ultra clean blowing, filling and spinning machine

- Oversized bottle blowing machine

Suzhou Xinsute Packaging Co., Ltd

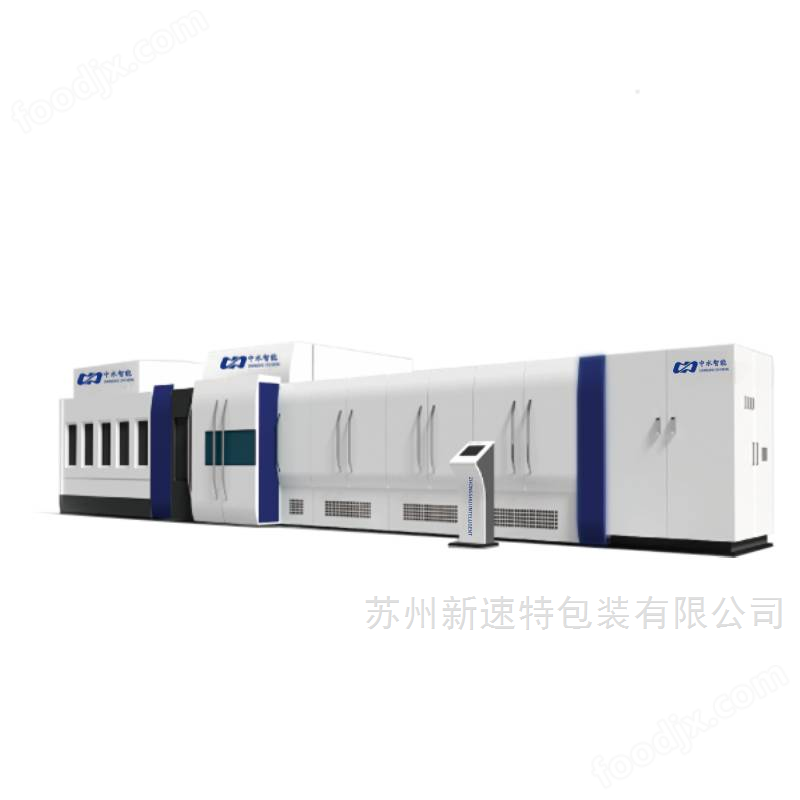

Small bottle blowing machine system

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Small bottle blowing machine system:

Blow Molding System

PET rotary blow molding machine: good production efficiency, infinitely flexible configuration.

PET rotary blowing machine: Excellent production efficiency, unlimited flexibility of configuration.

Compared with domestic peers, the energy consumption of intelligent bottle blowing in reclaimed water can save more than 30% of electricity and more than 10% of gas. Taking the 24000 blowing, filling, and spinning production line as an example, based on 22 hours of production per day and 280 days of production per year, only electricity (bottle blowing and air compression) is used, which can save about 550000 RMB per year.

Compared with the domestic counterparts, the energy consumption of blowing bottle can save more than 30% of electricity and save more than 10% of gas. Taking 24,000 blowing and rotating production lines as an example, according to the production of 22 hours per day and 280 days per year, only the electricity (blowing bottle and air pressure) can save about 550,000 yuan/year.

| 1. The manufacturer of the main components of the bottle blowing machine

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(Process flowchart)

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1. material

Bucket and feeding mechanism

Storing a certain amount of bottle preforms through a hopper to ensure the continuity of production; The conveyor belt in the hopper lifts the preforms to the billet sorting mechanism, making them neatly arranged in a row. The preforms enter the heating furnace equipment of the blow molding machine along the discharge track.

Small bottle blowing machine systemPerformance Description:

The bottle preforms are placed in the hopper and are monitored by the computer without the need for assistance. The amount of preforms can be automatically adjusted according to the production speed; According to different types of preforms, the output speed can be adjusted arbitrarily to ensure that the conveying volume of preforms is consistent with production; Rotating plastic conveyor belt and rotating drum conveyor ensure that bottle preforms are not damaged or contaminated during the transfer process.