-

Phone

15895689611

- Address

- Aseptic blowing, filling and spinning machine

- Carbonated beverage blowing, filling and spinning machine

- Bottled water blowing, filling and spinning machine

- homogenizer

- Hot filling, blowing, filling and spinning machine

- Non beverage blowing, filling and spinning machine

- Mixer

- Small bottle blowing machine

- Large packaging water blowing, filling and spinning machine

- Large bottle blowing machine

- Ultra clean blowing, filling and spinning machine

- Oversized bottle blowing machine

Suzhou Xinsute Packaging Co., Ltd

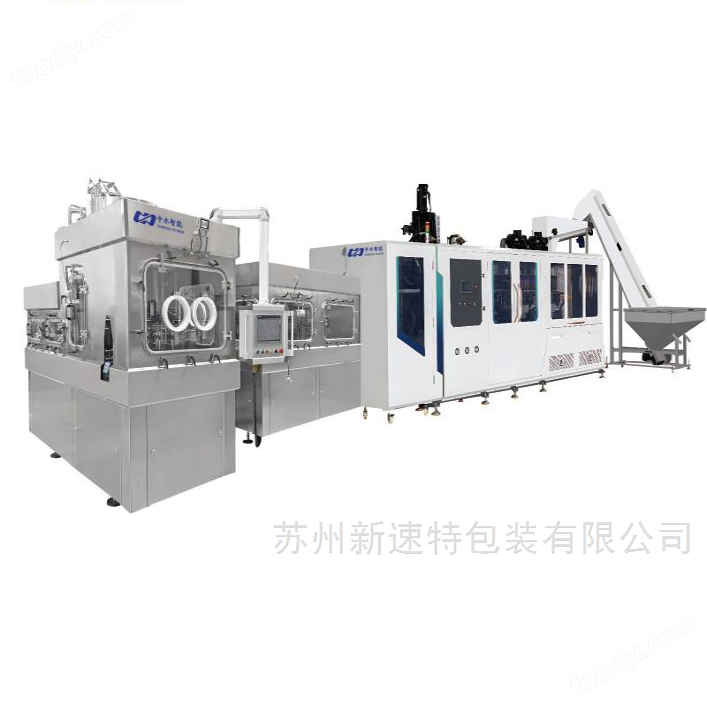

Non beverage blowing, filling and spinning machine

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

| Application scope: Applied scope: | Product range: Products scope: | Blow irrigation rotary machine series: Blowing-Filling-Capping Combiblock Series:: |

| Water, fruit and vegetable juice, tea, carbonated drinks, energy drinks, liquid milk, vegetable protein, alcohol, edible oil, condiments, daily chemicals and other products basically cover all PET bottle packaging products. Water, fruit and vegetable juice, tea, carbonated drinks, energy drinks, liquid milk, vegetable protein, alcohol, edible oil, condiments, daily chemicals and other products, basically covering all PET bottle packaging products. | Applicable containers: Suitable Container: Round PET bottle Square PET bottle Alien PET bottle Lightweight PET bottle Round PET bottle Square PET bottle Special-shaped PET bottle Light weight PET bottle Volume range: Volume Range: 200ML - 20L Filling temperature: Hot Filling (82-92℃), Medium Temperature Filling (68-75℃), Normal Temperature Filling (16-25℃), Low Temperature Cold Filling (4-15℃) production capacity Production Capacity: 4000 bottles/hour -72000 bottles/hour 4000 bottles/hour -72000 bottles/hour | Small bottle water blowing, filling and spinning machine Large bottle water blowing, filling and spinning machine Aseptic blowing, filling and spinning machine Ultra clean blowing, filling and spinning machine Carbonated beverage blowing, filling and spinning machine Hot filling, blowing, filling and spinning machine •Non beverage blowing, filling and spinning machine Small Bottled Water Combiblock Big-Container Combiblock Aseptic Combiblock Ultra-clean Combiblock CSD Combiblock Hot-fill Combiblock Non-beverage Combiblock |