-

E-mail

714107477@qq.com

-

Phone

15079107852

- Address

Weishu Machinery Technology (Shanghai) Co., Ltd

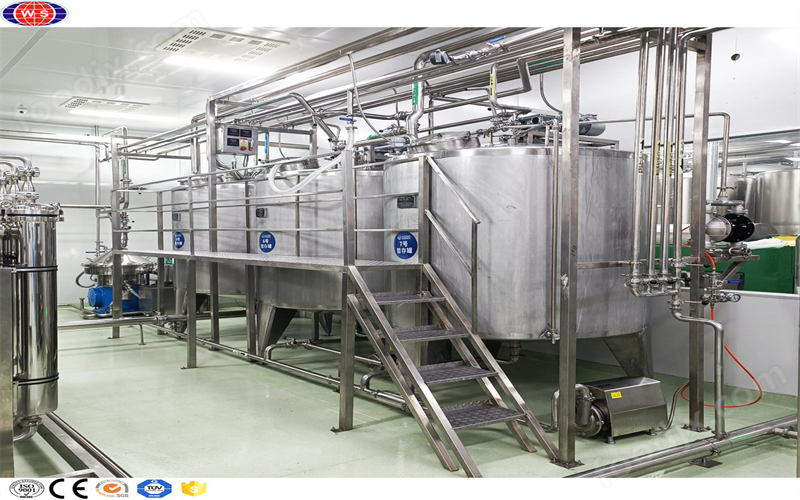

Milk and yogurt processing production line

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Milk and yogurt production line - a modular, highly clean, and fully compatible dairy intelligent manufacturing platform

Against the backdrop of accelerating the transformation of the dairy industry towards high quality, efficiency, and flexibility, the traditional "fixed process+single function" production line is no longer able to meet the practical needs of enterprises for multiple categories, fast iteration, and strict compliance. To this end, we have launched a new generationModular Milk and Yogurt Production Line——It is not a rigid combination of equipment, but a scalable, reconfigurable, and upgradable dairy manufacturing platform that truly achieves "multi functionality, flexible switching, and plug and play".

1、 Core design philosophy: Modules are products

This production line breaks the "whole line customization" mode and adoptsStandardized functional module designEach unit is an independent product with complete interfaces and performance parameters, including:

- M1 raw milk pretreatment moduleIntegrated filtering, cooling, temporary storage, and sampling functions, supporting constant temperature storage, equipped with a quick connect CIP interface;

- M2 Standardization and Homogenization ModuleIncluding a milk purifier, separator, and two-stage high-pressure homogenizer, with one click switching;

- M3 heat treatment moduleWe provide two sub modules: Babbitt (plate/tube) and UHT (direct/indirect), which customers can choose according to their needs and support later installation;

- M4 fermentation control moduleVertical jacketed fermentation tank with closed-loop temperature control, supporting single or multiple tanks in parallel;

- M5 aseptic filling moduleDivided into three independent models based on packaging form: cup packaging, bottle packaging, and brick packaging. The filling head can be quickly replaced and adapted to products of different viscosities;

- M6 intelligent cleaning stationIndependent modular design, including acid and alkali tank, hot water tank, circulation pump, conductivity detector, supporting automatic cleaning of 8 pipelines.

Each module is connected through a unified quick install clamp, standard electrical interface, and digital communication protocol, shortening the on-site installation cycle. In the future, expanding production only requires "adding modules" without rebuilding the production line.

2、 Product Highlights: Not only "usable", but also pursuing "easy to use"

-

Truly hygienic design

All material contact surfaces are made of SUS316L stainless steel to prevent liquid accumulation; All valves adopt diaphragm valves or ball valves; Welding endoscope inspection ensures no welding slag - eliminating the risk of microbial growth at the hardware level. -

High compatibility raw material adaptability

The production line can stably process a variety of milk sources: fresh cow's milk, reconstituted milk, goat milk, A2 milk, organic milk, and even plant-based milk (oat milk, soy milk) and milk based mixtures. By adjusting the homogenization pressure and sterilization parameters, different physical and chemical properties of raw materials can be adapted without replacing core components. -

Plug and play filling solution

The filling module adopts the "filling head quick change system" -

Embedded Intelligent Control System

Each module has its own edge computing unit, which runs independent control logic and is converged to the central HMI through industrial Ethernet. The system pre sets 10+dairy process templates (such as "Stir Yogurt Strawberry Flavor", "Greek Yogurt High Protein", "Pasteurized Fresh Milk Low Fat"). The operator selects the product name, and the system automatically loads a complete set of parameters such as temperature, time, speed, flow rate, etc., to prevent human errors in setting. -

Maintain friendly design

Key equipment (such as homogenizers and centrifuges) adopt front opening or side suction structures, and maintenance does not require dismantling the entire machine; The CIP system has a self diagnostic function that can indicate abnormalities such as insufficient concentration of cleaning solution and clogged spray balls; All motors and sensors are equipped with status indicator lights, reducing fault location time.