-

Phone

15895689611

- Address

- Aseptic blowing, filling and spinning machine

- Carbonated beverage blowing, filling and spinning machine

- Bottled water blowing, filling and spinning machine

- homogenizer

- Hot filling, blowing, filling and spinning machine

- Non beverage blowing, filling and spinning machine

- Mixer

- Small bottle blowing machine

- Large packaging water blowing, filling and spinning machine

- Large bottle blowing machine

- Ultra clean blowing, filling and spinning machine

- Oversized bottle blowing machine

Suzhou Xinsute Packaging Co., Ltd

Large packaging water blowing, filling and spinning machine

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Large packaging water blowing, filling and spinning machine

Scope of application:

Mainly used for packaging large capacity PET bottles for drinking water

Capacity Range:

1200 bottles/hour -16800 bottles/hour; Applicable bottle types 3000ml-7000ml

2400 bottles/hour -6000 bottles/hour; Applicable bottle types 7000ml-20000ml

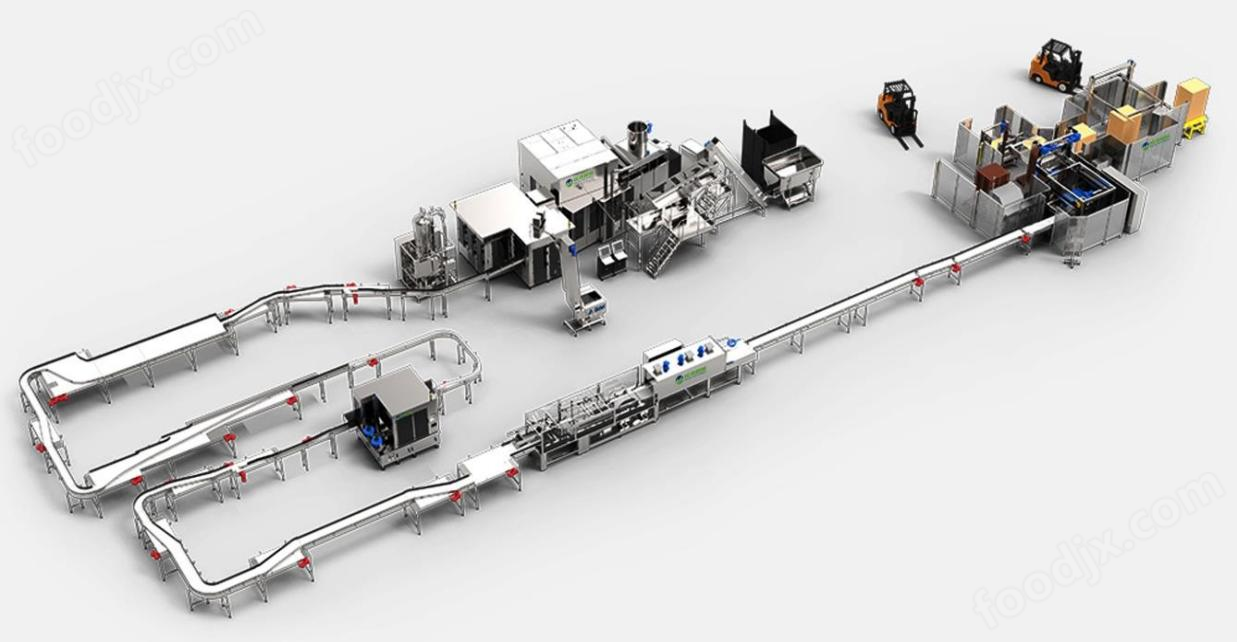

1. We create intelligent manufacturing solutions for different customers.

Establish a personalized and fully customized drinking water production line.

2. Selection of main equipment schemes (for reference)

3. Equipment selection principles:

1) The product has strong adaptability, complete functions, high degree of automation, mature stability, and low power consumption.

2) Stable performance, low failure rate, compact structure, easy operation and maintenance.

3) Save investment, reasonable price, good after-sales service, and good reputation.

4) Aim for the best domestic level as much as possible and prioritize the use of mature and advanced equipment to achieve the processing of its key processes.

2、 Dedicated to providing a full range of customized solutions for liquid packaging products

What kind of packaging do you need to design? Labeling and labeling of bottle body labels (self-adhesive or hot melt adhesive).

2. Your water source comes from underground wells or natural mountain spring water on the surface

3. The nominal capacity of the bottle is 500ml, and there are several other capacity bottles available

4. Different requirements for bottle mouth, bottle cap, and automation can affect equipment selection?

5. Our company provides turnkey engineering services for the entire factory, making customers more worry free and ensuring high coordination and stability before and after the entire production line.

Large packaging water blowing, filling and spinning machine:

|

| |||

|

| |||

|

| |||

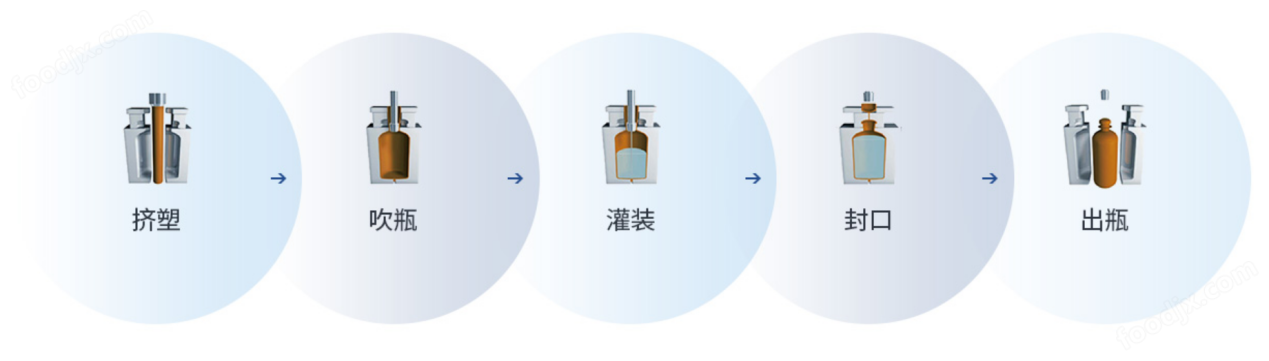

| Blowing, irrigating and spinning integrated machine Product Overview: Complete the complete actions of blowing, filling, and capping on a single device, from preform to bottle by a single machineliquidInnovative packaging technology for eco-friendly products. Efficient, environmentally friendly, clean, economical, and flexible, improving the production efficiency of the entire line and reducing overall production costs.

|

| Equipment category DeviceType | Small bottle water blowing, filling and spinning machine | bigbottleIntegrated water blowing, filling and spinning machine | Carbonated beverage blowing, filling and spinning machine | Hot filling, blowing, filling and spinning machine | Ultra clean blowing, filling and spinning machine | Non beverage blowing, filling and spinning machine |

| Scope of application: Application Scope: | Mainly used for packaging PET bottles for drinking water | Mainly used for packaging large capacity PET bottles for drinking water | Mainly used for packaging various carbonated beverages in PET bottles | Mainly used for packaging PET bottles of juice, tea, functional beverages, etc | Mainly used for packaging PET bottles of fruit juice, liquid milk, tea, functional beverages, etc | Mainly used for packaging PET bottles of beer, edible oil, soy sauce, vinegar, etc |

| Technical features: TechnicalFeature | Blowing machine: PET lightweight bottle: 55G bottle preform blowing 350ml,9.8G bottle preform blowing500ml; PET thick walled bottle: dairy thick walled bottle, blown with a wall thickness of 03-0.4mmUsed by dairy companies such as Yili and Mengniu; PET high barrier bottles: blow molded bottles that block light, oxygen, and carbon dioxide, used in high barrier fields such as beer, beverages, and pharmaceuticals; PET carbonated bottles: carbonated drinks, beer, and other carbonated beverages with a dissolved carbon dioxide content of 25-4.2倍CSD; PET sterile room temperature bottle: neutral protein beverages such as coffee, dairy products, fresh fruits and vegetables; Filling machine: 1.Filling valves designed for pure water or natural spring water: fast flow rate, precise liquid level control, independent and pollution-free reflux system, optimized valve body structure, achieving thorough CIP cleaning, representing the high level of domestic filling technology. 2.Waterline and hot filling valve: One valve can fill multiple different liquid products, compatible with beverages and water, and can be completed with one filling machine. 3.Gas containing and non gas containing beverage filling valves are compatible and shared. | |||||

PET bottle water production line packaging solution:

Applicable products:

Pure water, mineral water, mountain spring water, etc

Applicable containers:

Water packaging series: Various capacity square bottles and round PET bottles, glass bottles, cans, etc. can be customized for you.

3、 Our company provides customized PID process design drawings for bottled water production lines for customers

4、 Process flow of PET bottled water production line for whole plant engineering:

(How to build a complete bottled water production line? Our company provides professional technical solutions and reasonable planning suggestions for you.)

Process flow diagram of PET bottled drinking water production line

| Raw water | Select the 'Empty Bottle' option | 瓶坯 (preform) | ||||

| ↓ | ↓ | ↓ | ||||

| Water treatment) | Choose one | Preform finishing | ||||

| ↓ | ↓ | ↓ | ||||

| air(air) | product water(Product water) | Preform transfer | ||||

| ↓ | ↓ | ↓ | ↓ | |||

| Air purification) | → | filling(filling) | ← | Empty bottle transfer(Empty bottle transfer) | ← | Empty bottle blowing(Empty bottle blowing) |

| ↓ | ||||||

| ↓ | ||||||

| seal | ← | Empty lid sterilization | ← | Empty cover sorting | ||

| ↓ | ↑ | ↑ | ||||

| Product Inspection | Sterilization filtration | Empty lid | ||||

| ↓ | ↑ | |||||

| Product coding | compressed air | |||||

| ↓ | ||||||

| Inkjet coding inspection | ||||||

| ↓ | ||||||

| Product pressure free conveying | ||||||

| ↓ | ||||||

| Blow water on the bottle body | ||||||

| ↓ | ||||||

| Label attachment | ← | label | ||||

| ↓ | ||||||

| Tag detection | ||||||

| ↓ | ||||||

| Product outer packaging | ← | Paper box/film | ||||

| ↓ | ||||||

| Outer packaging coding | ||||||

| ↓ | ||||||

| outer packaging inspection | ||||||

| ↓ | ||||||

| palletizing | ← | Stacking board | ||||

| ↓ | ||||||

| Need film wrapping | → | finished product | → | Finished Goods Warehousing |

5. Introduction to the relevant advantages of our equipment

Blowing, irrigating, and spinning: Compared with domestic peers, it saves more than 30% of electricity and more than 10% of gas consumption. Taking the 24000 blowing, irrigating, and spinning production line as an example, based on 22 hours of production per day and 280 days of production per year, only electricity (blowing bottles and air compression) is used, which can save about 550000 yuan per year. Fully embody the design concepts of high efficiency, energy conservation, safety, and environmental protection.

Bottle blowing machine:

(We design multiple bottle types that are compatible and can be blown using a single bottle blowing machine)

Our company can blow 5.5g lightweight bottles to produce 350ml water bottles, and 9.8g lightweight bottles to produce 500ml water bottles;

The earliest development of a large bottle water blowing, filling, and spinning production line in China, producing 5-20 liter PET bottles for disposable packaging of drinking water;

Filling machine:

(If you plan to build a new factory: considering producing bottled water and also wanting to produce soda drinks, our filling machine can complete compatible filling of multiple materials with just one)

Waterline: A filling valve specially designed for the production of pure water or natural spring water, with fast flow rate, precise liquid level control, independent pollution-free reflux system, optimized valve body internal structure, and can achieve thorough CIP cleaning, representing the high level of domestic filling technology.

Filling method:

Mechanical valve filling, flow meter filling, weighing filling or laser fixed liquid level filling, etc

5、 A fully integrated intelligent solution for factory engineering, carefully designed and crafted for customers,

Please carefully refer to it for better choices!

6、 Tailored production lines to create intelligent and perfect factories.

Our company's blowing, filling, and capping machine technology features: The blowing, filling, and capping machine is a filling machinery equipment that integrates blowing, filling, and capping.

It mainly reduces intermediate processes such as conveying, empty bottle handling, stacking, and storage, improves packaging hygiene conditions, reduces cross contamination, enhances overall operational efficiency, and significantly reduces energy consumption, thereby reducing the comprehensive production cost of beverage production enterprises.

Suitable for PET bottle packaging of purified water, carbonated beverages, fruit juice, tea, liquid milk, liquid seasonings, and daily chemical products

Reasons for choosing the intelligent blowing, filling and spinning machine for reclaimed water

1. High cost-effectiveness

Based on years of exploration experience in the liquid packaging industry, we have devoted ourselves to the development of this fully automatic, high-yield, and MES intelligent management integrated blowing, filling, and spinning machine.

2. High cleanliness

This all-in-one machine is equipped with a precise quantitative meter to reduce overflow and dripping during the filling process. With the support of a fully automatic closed cycle in-situ cleaning system (CIP system), as well as technical means such as UV sterilization, ion dust removal, hydrogen peroxide sterilization, and sterile high-pressure air blowing, it not only ensures the foundation of production efficiency, but also ensures the cleanliness and hygiene of the entire edible oil packaging process.

3. High protection shell

The integrated blowing, filling and spinning machine adopts a solid floor frame and uses high-strength double-layer laminated explosion-proof tempered glass, which improves the machine's explosion-proof and scratch resistant capabilities. It is not only beautiful and elegant, but also safe and durable.

4. Compatible with various bottle sizes

In the production process where efficiency is king, a flexible production line can accelerate the production of products of different sizes. The blowing and filling rotary machine that adapts to various bottle sizes can reduce the time for engineers to debug and minimize losses caused by downtime.

Lightweight bottle packaging conforms to the theme of low-carbon economy. Compared with traditional beverage equipment, lightweight blowing, filling, and capping integrated equipment has the advantages of high efficiency, low cost, and low energy consumption. Replacing the traditional production process of blowing, filling, and capping single machine separation with blowing, filling, and capping integrated machines will be the development trend of the food packaging machinery industry.

1. Reduce the weight of bottle preforms

2. Reduce the thickness of the bottle wall

3. Optimize the preform heating system

4. Develop new bottle clamping devices and filling valves to achieve the filling of lightweight bottles;

5. Adopting a brand new lid system with detection device and automatic removal function

The integrated blowing, filling and spinning equipment is mainly used for mineral water, tea and fruit juice beverages, carbonated beverages, dairy beverages, etc.