-

E-mail

714107477@qq.com

-

Phone

15079107852

- Address

Weishu Machinery Technology (Shanghai) Co., Ltd

Dairy processing production line equipment

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Introduction to dairy processing equipment products

In today's increasingly popular concept of healthy consumption, dairy products, as an important source of high-quality protein, calcium, and various vitamins, have become an integral part of the daily diet of global residents. In order to meet the sustained growth demand of the market for high-quality, diversified, safe and reliable dairy products, modern dairy processing equipment has emerged. This type of equipment integrates advanced technologies from multiple fields such as machinery, automation, food engineering, and hygiene design, running through the complete production chain from raw milk receiving, pretreatment, sterilization, separation, homogenization, fermentation, filling to cleaning. It is the core support for ensuring dairy quality, improving production efficiency, and achieving intelligent manufacturing.

1、 Product Overview

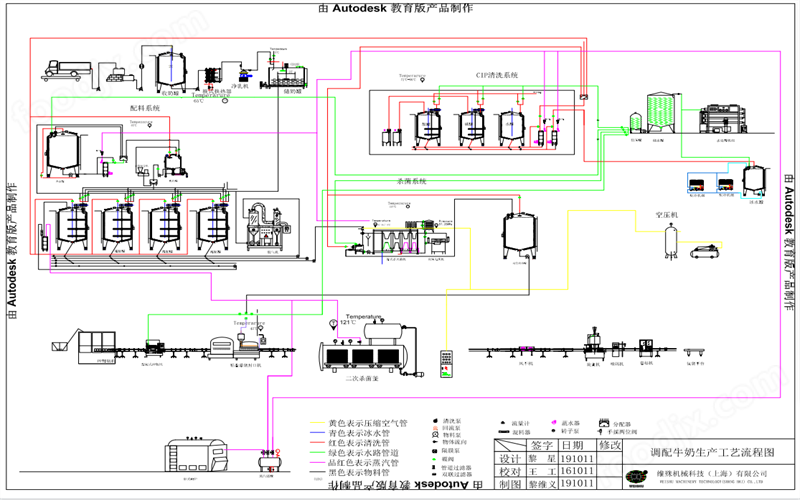

Dairy processing equipment refers to a specialized set of equipment used for physical, chemical, or biological processing of milk and other animal milk (such as goat milk, yak milk, etc.) to produce liquid milk, yogurt, cheese, cream, milk powder, condensed milk, whey protein, and other products. According to the process flow, it mainly includes: raw milk storage system, milk purifier, pasteurizer, UHT ultra-high temperature instantaneous sterilizer, homogenizer, fermentation tank, mixing tank, separator, concentration equipment, spray drying tower, sterile filling machine, CIP cleaning system and central control system.

The entire equipment strictly follows food grade hygiene standards, is made of all stainless steel material, has high-precision polishing on the inner surface, is easy to clean, eliminates the risk of microbial growth, and ensures the safety and controllability of dairy products from source to finished product.

2、 Core equipment functions and technical characteristics

-

Raw milk receiving and storage system

Including milk tanker docking platform, filter, cooling plate replacement, and low-temperature milk storage tank. Equipped with automatic weighing, sampling, acidity detection, and fast fat/protein analyzer to achieve digital management of raw milk quality. -

Milk Purification and Separation Equipment

The high-speed centrifugal milk purifier can efficiently remove impurities, somatic cells, and some microorganisms from raw milk; The cream separator accurately separates skim milk and cream based on density differences. -

Sterilization system

- PasteurizerAdopting plate or tube heat exchangers to preserve the nutrition and flavor of dairy products, suitable for the production of fresh milk and yogurt base materials.

- UHT ultra-high temperature sterilization machineInstant sterilization, combined with aseptic filling, enables the product to have a shelf life of 6-12 months at room temperature, widely used in the production of room temperature milk and blended milk.

-

homogenizer

By using high pressure to break the fat globules and prevent milk fat from floating, the stability and delicacy of the product are improved. Adopting ceramic plunger and two-stage homogeneous design, it runs smoothly and has a long service life. -

Fermentation and blending system

The constant temperature fermentation tank is equipped with jacket temperature control, sterile inoculation port, and online pH monitoring, suitable for fermented dairy products such as yogurt and kefir; The mixing tank is used to add auxiliary materials such as sugar, stabilizers, juice, etc., to achieve precise ratio and uniform mixing. -

Concentrating and drying equipment

The multi effect falling film evaporator can concentrate milk to 45-50% solids, which is energy-saving and efficient; The spray drying tower adopts centrifugal or pressure atomization to instantly dry the concentrated milk into milk powder particles, with accurate water control and good solubility. -

Aseptic filling and packaging line

Supports multiple packaging forms, with high filling accuracy and fast speed, and integrates functions such as date printing, leak detection, weighing and removal. -

CIP/SIP Fully Automatic Cleaning and Sterilization System

The entire pipeline and equipment support one click online cleaning (CIP) and online sterilization (SIP), using food grade cleaning agents. The program can be set, recorded, and traced to ensure cleanliness after each batch of production and prevent cross contamination.

3、 Advantages of Intelligence and Green Manufacturing

Modern dairy processing equipment deeply integrates industrial Internet of Things technology, equipped with control systems, to achieve:

- Real time monitoring and automatic adjustment of the entire process parameters

- Suggestions for energy consumption data collection and optimization

- Fault warning and remote diagnosis

- Batch traceability and electronic batch recording

At the same time, the equipment has outstanding energy-saving performance: the heat recovery system can use the waste heat from the sterilization section to preheat the feed, with an energy-saving rate of over 40%; Variable frequency drive technology dynamically adjusts motor power based on load to reduce power consumption; The water-saving CIP program reduces cleaning water by 30%.

4、 Widely applicable in various fields

This series of equipment is suitable for various dairy production enterprises, including:

- Room temperature/low-temperature liquid milk production line

- Flavored yogurt, Greek yogurt, and drinking yogurt production lines

- Cheese (cheese, processed cheese) processing system

- Production lines for infant formula milk powder, adult formula milk powder, and special medical use formula milk powder

- Deep processing projects for dairy ingredients such as cream, butter, whey powder, etc

Whether it is a small-scale farm self processing project with a daily processing capacity of 10 tons or a large-scale dairy group with a daily processing capacity of over 1000 tons, modular and scalable overall solutions can be provided.

5、 Parameters

| Device Model | hourly output | steam consumption | power consumption | Required workshop area |

| SWBSN-2000 | 2000 bottles | 300KG | 60KW | 300㎡ |

| SWBSN-4000 | 4000 bottles | 500KG | 80KW | 500㎡ |

| SWBSN-6000 | 6000 bottles | 600KG | 120KW | 600㎡ |

| SWBSN-10000 | 10000 bottles | 1000KG | 150KW | 1000㎡ |