-

E-mail

2835033935@qq.com

-

Phone

18366586555

-

Address

6755 Xinghua East Road, Mizhou Street, Zhucheng City

Zhucheng Meikang Food Machinery Co., Ltd

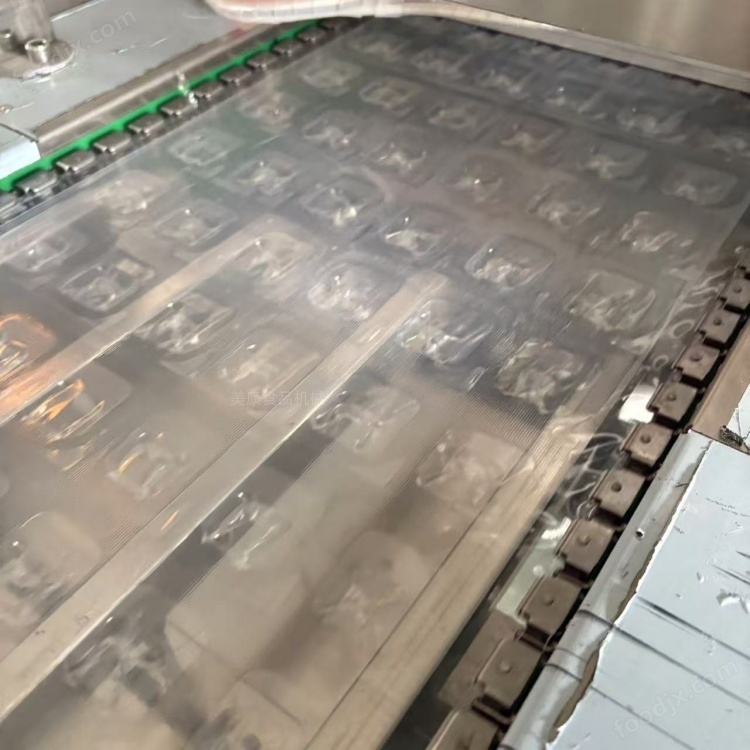

Continuous packaging machine for sweet potato jerky, boneless chicken feet vacuum packaging equipment

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Continuous packaging machine for sweet potato jerky, boneless chicken feet vacuum packaging equipmentConfiguration Description:

(1) The equipment is equipped with a German original 200 (external) high vacuum pollution-free stretching packaging machine vacuum pump, which has high vacuum degree and fast pumping speed!

(2) Equipped with Italian photoelectric tracking system and optical film All colored films can be used, and the outer packaging is beautiful, accurate, and error free.

(3) Equipped with a heat sealing studio cooling system, the sealing is aesthetically pleasing

(4) The phase failure protection system, such as automatic shutdown of equipment due to phase loss in the power grid, protects the machine from damage .

(5) Equipped with a leakage protection system, the device automatically cuts off the power supply in case of leakage, protecting the personal safety of operators

(6) The phase sequence protection system automatically shuts down the machine when the power system is in reverse phase or caused by wiring, protecting the machine from damage

(7) Equipped with imported Italian stainless steel chains

8) Pneumatic components use SMC products from Japan

(9) The frame is made of aluminum magnesium alloy, which has high strength, good straightness, and is not easily deformed. .

(10) Mitsubishi "brand 10.4" color touch screen from Japan, Mitsubishi programmable controller with 3G60M memory version (with analysis of small fault cause alarm and touch alarm fault point analysis and processing function, fault reset function), Mitsubishi Sufu speed, Mitsubishi temperature module, Mitsubishi motion control module, American Bonner color code sensor, Japanese Izumi small relay, emergency stop button, French Schneider, contactor, micro segment and other electrical appliances. Yangming solid state relay, phase sequence protector, imported from Taiwan, China, China, and Kaikun fault alarm imported from South Korea

(11) According to user requirements, it can be equipped with Mitsubishi servo coding system or coding system from Japan. Or laser coding machine (optional)

(12) Equipped with upper and lower film correction (this function is very important, as the manufacturer of the film may cause uneven film end faces during wrapping or transportation, resulting in deviation of the upper film, causing the pattern to deviate from the product and affecting the appearance. Sometimes, a dedicated person is needed to guard here and adjust the film. After using the upper film correction, if the film deviates, the computer will automatically sense and correct it.)

Equipment parameters of 420 fully automatic stretch film vacuum packaging machine:

Upper film width: 392-394mm Lower film width: 422mm

Power supply: 380V50HZ vacuum pump pumping speed: 100-300m3/h

Average power supply: 13kw Compressed air pressure: 0.6MP

Dimensions: 6500 * 1000 * 1850 Total weight: 2000kg

Continuous packaging machine for sweet potato jerky, boneless chicken feet vacuum packaging equipmentAfter-sales service

1. The company is responsible for on-site installation and debugging of the equipment provided. Ensure that the goods provided are manufactured by the original manufacturer, obtained through legal sales channels, brand new, and unused. Ensure the long-term quality and stable performance of the goods under normal operating conditions, and the products comply with national and industry standards.

2. Implement 12Free one month warranty and lifetime maintenance.

3. Provide a detailed training plan: provide free consultation and guidance on all professional issues during use, offer long-term technical support and after-sales service.

4. Provide a complete set of technical documents, after-sales technical support for the system, spare parts, and follow-up technical consulting services; Provide consulting services for supporting equipment; Provide professional technical training to users and designated personnel on the basic application, product maintenance, troubleshooting, and other related aspects of the products sold. Enable relevant personnel to proficiently use the equipment and perform simple setup, maintenance, and upkeep of the equipment.