-

E-mail

ydb@kexinshiye.com

-

Phone

13592643205,15838093093

-

Address

Binhai Industrial Park, Longwan District, Wenzhou City

Wenzhou Kexin Light Industry Machinery Co., Ltd

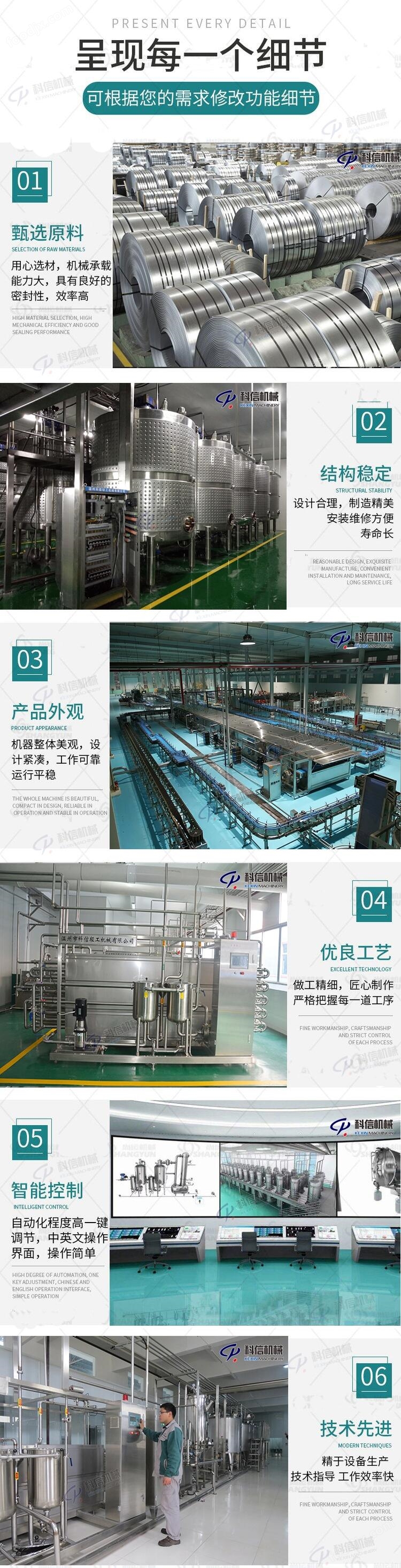

Complete set of fully automatic apple cider vinegar beverage processing equipment

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Raw material pretreatment and fermentation system:

The production line starts with high efficiencyRaw material processing systemIt can clean, crush, and press raw materials such as apples to prepare high-quality fermentation pulp.

Intelligent fermentation systemIt is the core process, including enclosedAlcohol fermentation tankWith dedicatedAcetic acid fermentation tankThe equipment is made of food grade materials and equipped with precise temperature control and ventilation mixing devices to provide a growth environment for yeast and acetic acid bacteria, ensuring stable and sufficient fermentation process, effectively converting and accumulating flavor substances.

Allocation and filtering system:

Fermented vinegar entersPrecision dispensing systemIt is automatically mixed online with processed water, sugar, and other additives, with precise formula control to ensure consistent product taste.

Multi stage filtration systemFollowing closely behind, it effectively removes impurities, bacteria, and unstable components, giving the wine a clear appearance and a long-term stable shelf life.

Aseptic filling and capping system:

The prepared liquid materialInstantaneous sterilization systemFast processing, preserving flavor and nutrition while killing microorganisms.

The processed liquid enters a high-speed, clean environmentFully automatic filling and sealing machineThis device can complete precise quantitative filling and instant sealing in a clean environment, eliminating secondary pollution and ensuring product safety.

Post packaging and intelligent control:

The filled product passes throughPour bottle sterilizationorSpray type pasteurization tunnelProvide secondary protection and go throughEfficient blow drying.

Finally, byAutomated packaging systemComplete the processes of labeling, coding, film wrapping, or packaging to form a neat finished product.

The entire line is integrated and scheduled by the control systemRealize visual monitoring and data management from feeding to finished products, greatly improving production efficiency and stability.

Wenzhou Kexin Light Industry Machinery Co., Ltd

Headquarters Address: No. 540 Binhai 3rd Road, Longwan District, Wenzhou City, Zhejiang Province

Kexin Machinery Henan Marketing Center

Address: Building 3, Phase II, Intelligent Food Machinery Equipment Park, Intersection of Yushan Road and Fazhan Road, Zhaoling District, Luohe City, Henan Province