-

E-mail

znzbjc@163.com

-

Phone

18754369535

-

Address

108 Mastercard Road, Xingfu Town, Boxing County, Binzhou City, Shandong Province

Product Categories

Shandong Shangding Intelligent Equipment Co., Ltd

Chopping machine

NegotiableUpdate on 01/08

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

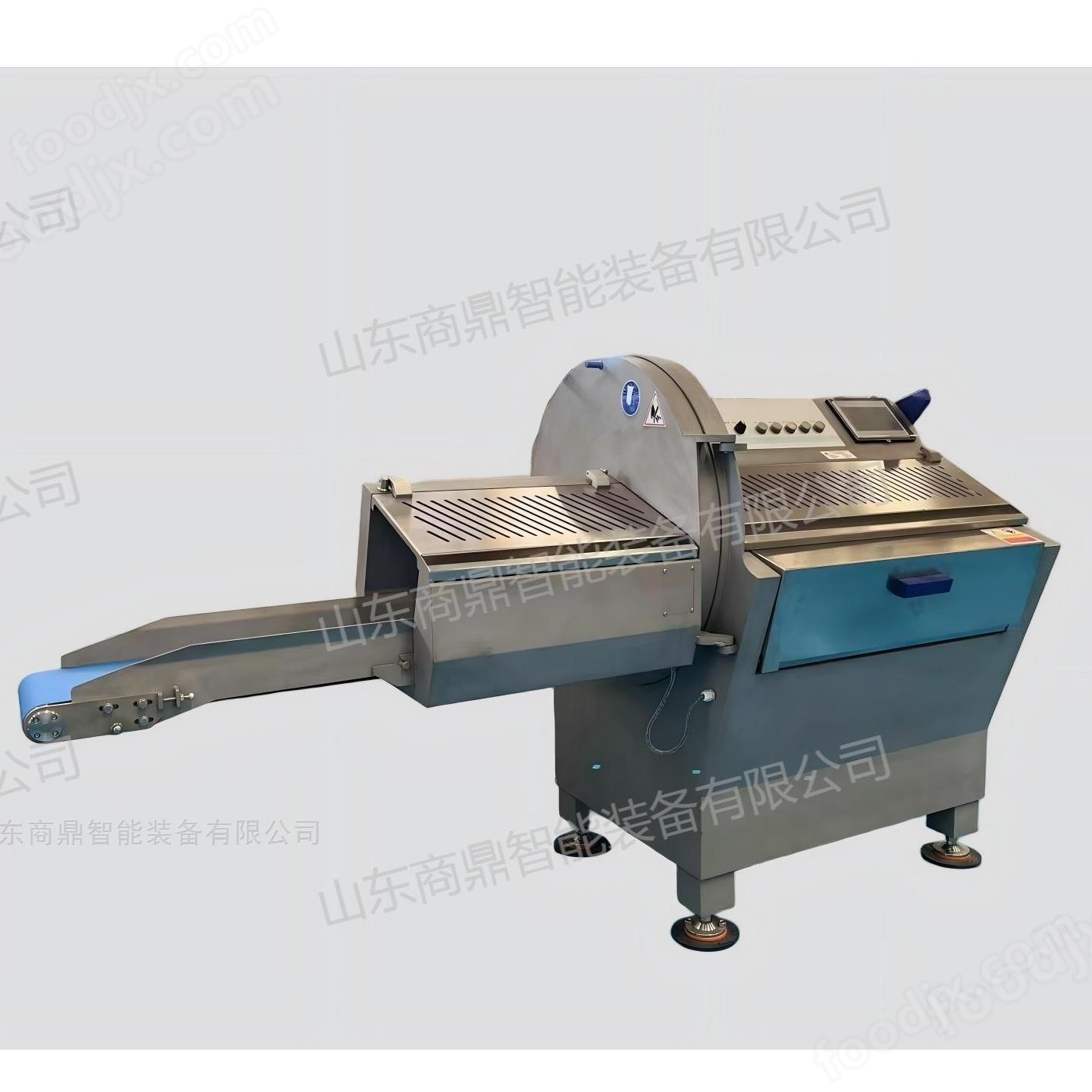

Chopping machine is a safe and efficient cutting equipment that places materials on a material table with card loading function. It uses a linear guide rail to limit the direction, and a servo motor combined with a precision ball screw to provide power while ensuring a walking distance of 0.01mm. After the materials are placed stably, the feeding shaft matches the blade speed and slowly feeds forward to ensure accurate and stable size specifications. Can be used for cutting sausages, ham, bacon, meat, fish and other meats, with adjustable cutting thickness.

Product Details

1、 Product Introduction:

Chopping machineIt is a safe and efficient meat cutting equipment that places materials on a feeding platform with card loading function. It uses a linear guide to limit the direction, and a servo motor combined with a precision ball screw provides power while ensuring a walking distance of 0.01mm. After the materials are placed stably, the feeding shaft matches the speed of the blade and slowly feeds forward to ensure accurate and stable size specifications.

This control system has multiple cutting functions: continuous mode, continuous feeding action, higher efficiency; This mode is suitable for ingredients with low height or thickness requirements; Intermittent mode, intelligent calculation of feed according to blade position, intermittent action; This mode is suitable for precise thickness and stable size of each piece;

2、 Function Overview:

Products such as sausages, ham, bacon, meat, fish, chicken, duck, and cheese products can be cut with adjustable thickness;

Efficient and dynamic feeding system, saving feeding time;

Intelligent cutting features prevent product slippage and ensure product quality;

Adopting return restrictions to save time;

Maximum feed size: 680mm, maximum feed cross-section: 170mm * 150mm, cutting thickness: 1-32mm.

3、 Parameters:

3、 Parameters:

| unit | unit | content |

| Slice thickness | mm | 0.5-30 |

| dimensional accuracy | mm | 0.1 |

| Adaptation temperature | ℃ | -7-0 |

| cutting | power | 2.5KW |

| speed(max) | 285piece/divide | |

| feeding | power | 1KW |

4、 Equipment composition:

| name | function |

| grip | Different specifications of ingredients can be fixed on the loading platform |

| feeding | Control the length of ingredients, i.e. the thickness of each cut |

| cutting | Cutting with blade |

| Material receiving box | Collect crushed materials |

| touch screen | By touching the display area of the screen with your hand, you can operate the machine |

| control box | Equipped with a series of control components such as controllers and servo units |

5、 Attention:

1. Safety precautions when starting homework

Before carrying out mechanical operation, please make sure to perform a start-up inspection.

danger

Cables and wires with damaged outer skin pose a risk of leakage and electric shock. Before connecting the power supply, it is necessary to carefully confirm whether there is any damage. If there is a possibility of damage or disconnection, immediately entrust personnel with electrical engineering qualifications to take appropriate measures.

Warning:

Confirm the presence or absence of machine malfunctions and take preventive measures. Please be sure to carry out a start operation inspection.

Please follow the instructions in the user manual to turn on and off the power supply.

Confirm whether the safety device is functioning properly according to the instructions in the user manual.

Immediately contact maintenance personnel or our company's service department upon discovering any abnormalities.

All covers are not damaged or unsuitable.

Ensure that the workspace is sufficiently spacious and clear of obstacles on the job.

To prevent falling accidents, remove the spilled oil and water on the ground and keep the ground and passages dry regularly.

Processing objects and mechanical attachments are susceptible to damage, and wearing open clothing, rings, bracelets, and watches is prohibited.

Make sure to tie up your long hair to prevent it from being caught up by machinery.

Individuals who experience dizziness due to alcohol consumption, medication use, or illness should not be allowed to operate machinery.

Note:

After a long period of mechanical shutdown, it is necessary to confirm that there are no abnormalities in the mechanical action, sound, and lubrication. When abnormal sounds, abnormal heating, and abnormal movements are detected, immediately cut off the power supply and contact the person in charge of maintenance to take necessary measures.

Connect the power supply and fully implement adaptive operation.

2. Safety precautions during operation

danger

It is prohibited to remove the safety cover and any part of the safety device of the power supply, or to operate it in a state where the high voltage terminals are exposed. Correctly understand the method of stopping the machine in emergency situations before operating it.

Warning:

When picking up materials, be sure to stop the equipment and confirm that the workbench has stopped before proceeding with the operation.

Confirm that there are no people or obstacles within the movable range of the machinery before operating.

When mechanical automatic operation stops due to certain reasons, clarify the reason for the stop until it can be determined

Before approving the recovery program, do not restart it as it is dangerous to restart in a state where the reason is unclear.

It is prohibited to remove the limit switch and change its position.

Note:

Do not use wet hands on switches and buttons, as it may cause incorrect actions and malfunctions.

When operating switches and buttons, be sure to confirm if they are correct before proceeding.

During automatic operation, do not neglect to touch switches and buttons, and do not rely on machinery to regularly clean the inside of the machine.

When minor abnormalities are found during operation, immediately stop the machinery and discuss with the person in charge.

When displaying alarm information, quickly process it.

3.Safety precautions during maintenance operations

danger

During maintenance operations, in order to prevent others from mistakenly connecting the main power supply or touching the operation screen, a sign and tag with the words' Do not touch machinery during maintenance operations' should be hung in a prominent position.

Especially when conducting maintenance inside the electrical control box, cut off the factory's main power supply. And do not open the door for several minutes due to residual voltage. Ignoring warnings can lead to serious injuries, even electrocution and other major accidents.

Warning:

Without the permission of our company, it is prohibited to remove or change limit switches and baffles.

After turning off the main power switch, do not touch the regenerative discharge unit for a short period of time.

Note:

Only qualified personnel are allowed to carry out maintenance operations.

The responsible personnel shall confirm the results of the implementation of the homework.

Implement the regular inspection items recorded in the user manual.

Follow all procedures and methods in the user manual for operation. If you have any questions or concerns, please consult our company immediately.

4. Safety precautions at the end of homework

When ending the mechanical operation, please make sure to conduct a job completion check.

Please follow the procedure outlined in the user manual to cut off the power supply.

Cut off the main power switch and lock it. After the machine stops operating completely, clean the machine and peripheral equipment.

At the end of the assignment, confirm that all parts of the machinery are in their initial state.

5.Other safety precautions

Warning:

No modifications or changes that reduce mechanical safety are allowed.

Immediately cut off the main power switch during a power outage.

During intense thunderstorms and frequent power outages, mechanical operation is suspended to prevent accidents caused by abnormal power supply.

Note:

Ensure that the workspace is sufficiently spacious and clear of obstacles on the job.

When replacing consumables, always use the products designated by our company.

Similar Product Recommend