-

Phone

15895689611

- Address

- Aseptic blowing, filling and spinning machine

- Carbonated beverage blowing, filling and spinning machine

- Bottled water blowing, filling and spinning machine

- homogenizer

- Hot filling, blowing, filling and spinning machine

- Non beverage blowing, filling and spinning machine

- Mixer

- Small bottle blowing machine

- Large packaging water blowing, filling and spinning machine

- Large bottle blowing machine

- Ultra clean blowing, filling and spinning machine

- Oversized bottle blowing machine

Suzhou Xinsute Packaging Co., Ltd

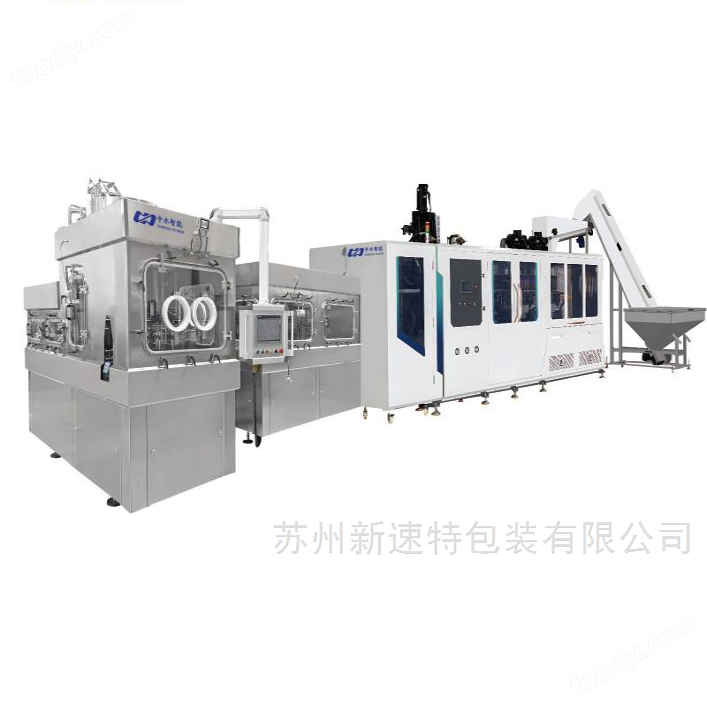

Carbonated beverage blowing, filling and spinning machine

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Carbonated beverage blowing, filling and spinning machine

Scope of application:

Mainly used for packaging various carbonated beverages in PET bottles

Capacity Range:

10000 bottles/hour -72000 bottles/hour (500ml); Suitable bottle size 150ml-2000ml

1. We create intelligent manufacturing solutions for different customers.

2. Build a personalized and customized complete drinking water production line.

3. Selection of main equipment schemes (for reference)

4. Equipment selection principles:

1) The product has strong adaptability, complete functions, high degree of automation, mature stability, and low power consumption.

2) Stable performance, low failure rate, compact structure, easy operation and maintenance.

3) Save investment, reasonable price, good after-sales service, and good reputation.

4) Aim at the domestic advanced level as much as possible and prioritize the use of mature and advanced equipment to achieve the processing of its key processes.

2、 Dedicated to providing a full range of customized solutions for liquid packaging products

What kind of packaging do you need to design? Labeling and labeling of bottle body labels (self-adhesive or hot melt adhesive).

2. Your water source comes from underground wells or natural mountain spring water on the surface

3. The nominal capacity of the bottle is 500ml, and there are several other capacity bottles available

4. Different requirements for bottle mouth, bottle cap, and automation can affect equipment selection?

5. Our company provides turnkey engineering services for the entire factory, making customers more worry free and ensuring high coordination and stability before and after the entire production line.

PET bottle blowing, filling and spinning integrated machine production line:

Blowing, irrigating and spinning integrated machine

Blowing-Filling-Capping Combiblock

Product Overview:

Complete the complete actions of blowing, filling, and capping on a single device, from preform to bottle by a single machineliquidInnovative packaging technology for eco-friendly products.

Efficient, environmentally friendly, clean, economical, and flexible, improving the production efficiency of the entire line and reducing overall production costs.

| Application scope: Applied scope: | Product range: Products scope: | Blow irrigation rotary machine series: Blowing-Filling-Capping CombiblockSeries:: |

| Water, fruit and vegetable juice, tea, carbonated drinks, energy drinks, liquid milk, vegetable protein, alcohol, edible oil, condiments, daily chemicals, etcThe product basically covers all PET bottle packaging products. Water, fruit and vegetable juice, tea, carbonated drinks, energy drinks, liquid milk, vegetable protein, alcohol, edible oil, condiments, daily chemicals and other products, basically covering all PET bottle packaging products. | Applicable containers: Suitable Container: Round PET bottle Square PET bottle Alien PET bottle Lightweight PET bottle Round PET bottle Square PET bottle Special-shaped PET bottle Light weight PET bottle Volume range: VolumeRange: 200ML - 20L Filling temperature: Hot Filling (82-92℃), Medium Temperature Filling (68-75℃), Normal Temperature Filling (16-25℃), Low Temperature Cold Filling (4-15℃) production capacity Production Capacity: 4000 bottles/hour -72000 bottles/hour 4000 bottles/hour -72000 bottles/hour | Small bottle water blowing, filling and spinning machine Large bottle water blowing, filling and spinning machine Aseptic blowing, filling and spinning machine Ultra clean blowing, filling and spinning machine Carbonated beverage blowing, filling and spinning machine Hot filling, blowing, filling and spinning machine Non beverage blowing, filling and spinning machine Small Bottled Water Combiblock Big-Container Combiblock Aseptic Combiblock Ultra-clean Combiblock CSD Combiblock Hot-fill Combiblock |

| Device Type | Small bottle water blowing, filling and spinning machine SmallBottled Water Combiblock

| bigbottleIntegrated water blowing, filling and spinning machine BigBottled Water Combiblock | Carbonated beverage blowing, filling and spinning machine CSD Combiblock

| Hot filling, blowing, filling and spinning machine Hot-fill Combiblock

| Ultra clean blowing, filling and spinning machine Ultra-clean Combiblock

| Non beverage blowing, filling and spinning machine Non-beverage Combiblock

|

| Scope of application: Application Scope: | Mainly used for packaging PET bottles for drinking water Mainly used for PET-bottle drinking water packaging | Mainly used for packaging large capacity PET bottles for drinking water Mainly used for PET-bottle drinking water packaging | Mainly used for packaging various carbonated beverages in PET bottles Mainly used for packaging various types of PET bottles of carbonated beverages | Mainly used for packaging PET bottles of juice, tea, functional beverages, etc | Mainly used for packaging PET bottles of fruit juice, liquid milk, tea, functional beverages, etc | Mainly used for packaging PET bottles of beer, edible oil, soy sauce, vinegar, etc

|

| Capacity Range: | 12000 bottles/hour -72000 bottles/hour (500 ml); Suitable bottle size 150ml-1500ml | 1200 bottles/hour -16800 bottles/hour; Applicable bottle types 3000ml-7000ml 1200 bottles/hour -16800 bottles/hour; for the bottle types of 3L-7L

| 10000 bottles/hour -72000 bottles/hour (500 ml); Suitable bottle size 150ml-2000ml

| 9000 bottles/hour -48000 bottles/hour (500 ml); Suitable bottle size 150ml-2000ml 9000 bottles/hour -48000 bottles/hour(500 ml); for the bottle types of 150ml-2000ml | 5000 bottles/hour -48000 bottles/hour; Suitable bottle size 150ml-1500ml

| 3000 bottles/hour -48000 bottles/hour (500 ml); Suitable bottle size 150ml-2500ml 3000 bottles/hour -48000 bottles/hour(500 ml); for the bottle types of 150ml-2500ml 1200 bottles/hour -16800 bottles/hour(500 ml); for the bottle types of 1800ml-6000ml

|

| Technical features: Technical Feature | Blowing machine: PET lightweight bottle: 55G bottle preform blowing 350ml,9.8G bottle preform blowing500ml; PET lightweight bottle: 5.5g bottle embryo blown 350ml,9.8g bottle embryo blown 500ml; PET thick walled bottle: dairy thick walled bottle, blown with a wall thickness of 03-0.4mmUsed by dairy companies such as Yili and Mengniu; PET thick wall bottle: dairy thick wall bottle, blown wall thickness 0.3-0.4mm, Yili, Mengniu and other dairy enterprises use; PET high barrier bottles: blow molded bottles that block light, oxygen, and carbon dioxide, used in high barrier fields such as beer, beverages, and pharmaceuticals; PET high barrier bottle: blow block light, block oxygen, block carbon dioxide bottle, used in beer, beverage, pharmaceutical and other high barrier fields; PET carbonated bottles: carbonated drinks, beer, and other carbonated beverages with a dissolved carbon dioxide content of 25-4.2倍CSD; PET bottle containing steam: carbonates, beer and other beverages containing steam, carbon dioxide dissolved content 2.5-4.2 times CSD; PET sterile room temperature bottle: neutral protein beverages such as coffee, dairy products, fresh fruits and vegetables; PET sterile room temperature bottle: coffee, milk products, fresh fruits and vegetables and other neutral protein drinks; Filling machine: 1. Filling valves designed for pure water or natural spring water: fast flow rate, precise liquid level control, independent and pollution-free reflux system, optimized valve body structure, achieving thorough CIP cleaning, representing the high level of domestic filling technology. The filling valve designed by pure water or natural spring water: fast flow rate, accurate level control, independent pollution-free with reflux system, optimized valve body structure, complete CIP cleaning, representing the highest level of domestic filling technology. 2. Waterline and hot filling valve: One valve can fill multiple different liquid products, compatible with beverages and water, and can be completed with one filling machine. Water line and hot filling valve: One valve fills many different liquid products, compatible beverages and water can be done with one filling machine. 3. Gas containing and non gas containing beverage filling valves are compatible and shared. Gas-filled and non-gas-filled beverage filling valves are compatible. | |||||