-

E-mail

znzbjc@163.com

-

Phone

18754369535

-

Address

108 Mastercard Road, Xingfu Town, Boxing County, Binzhou City, Shandong Province

Product Categories

Shandong Shangding Intelligent Equipment Co., Ltd

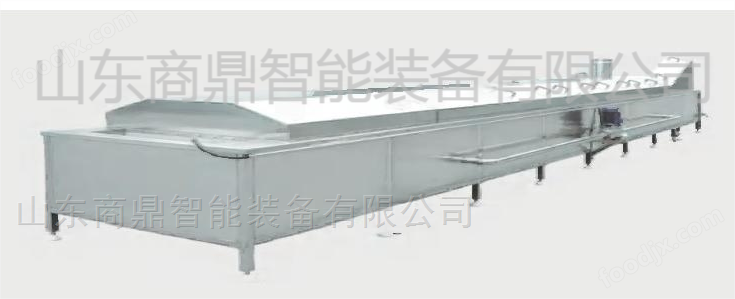

Blanching production line

NegotiableUpdate on 01/08

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

The blanching production line is an automatic low-temperature sterilization equipment that can achieve sterilization cooling, suitable for sterilization in the food industry such as bagged, canned, pickled vegetables, pickled vegetables, pickled vegetables, jams, soy products, etc. The sterilization temperature and speed can be set according to the process requirements, which solves the problem of "arbitrariness" caused by low automation in the sterilization process and strengthens "consistency", greatly improving the success rate of sterilization.

Product Details

The blanching production lineProduct Overview:

Blanching production lineIt is an automatic low-temperature sterilization equipment that can achieve sterilization cooling, suitable for sterilization in the food field such as bagged, canned, pickled vegetables, pickles, pickled vegetables, jam, soy products, etc. The sterilization temperature and speed can be set according to the process requirements, which solves the problem of "arbitrariness" caused by low automation in the sterilization process and strengthens "consistency", greatly improving the success rate of sterilization.

Functional Overview:

★ Sterilization and blanching of applicable materials;

The heating method adopts steam heating, with multiple heating methods to stabilize the temperature inside the tank, and precise temperature control for multi zone heating.;

The box is equipped with insulation layer, built-in steam pipeline, steam direct heating method, steam consumption of 300-350kg/h;

Equipped with a variable frequency speed regulating motor, the blanching time can be adjusted;

Equipped with an electromagnetic valve for automatic control of water temperature and a separate control system, the water temperature control is more precise.

★ PLC computer fully automatic control, can set multiple programs to meet different customer needs

Features:

★ The equipment reduces noise, has strong practicality, is easy to operate, and is easy to maintain;

Intelligent control, continuous production, improving production and processing efficiency, and saving manpower;

Except for the motor and electrical components, the body is made of SUS304 stainless steel material, which meets the safety requirements of food processing.

Installation and operation

3.1 Equipment Installation

3.1.1 Place the equipment in a horizontal workspace to ensure that the machine is placed smoothly and reliably.

Before use, check all parts to ensure that fasteners are not loose during transportation, and that switches and power supplies are not damaged due to transportation.

3.2 Trial operation

3.2.1 Confirm that the power supply voltage matches the rated voltage of the machine. A professional electrician is required to connect the power supply, start the motor, and check if the conveyor belt is rotating correctly. Otherwise, adjust the wiring.

3.3 Safety Operation Instructions

3.3.1 Safety protection devices

Do not dismantle the safety protection device of the equipment at will to avoid danger.

3.3.2 Precautions

a. When using the equipment, it is not advisable to put too many materials to avoid affecting the normal use of the equipment.

b. Do not press your hands on the conveyor belt during equipment operation to avoid danger.

c. During machine maintenance, do not turn on the switch to avoid danger.

d. During machine operation, no maintenance or upkeep is allowed in any form to avoid personal injury.

e. If an abnormality occurs during machine operation, the power must be immediately cut off and the machine can only be used again after the fault is resolved.

3.3.3 Maintenance and upkeep

Note: All maintenance and upkeep work must be carried out with the power disconnected.

a. Clean the equipment after each use.

b. Regularly check the tightness of the chain and take corresponding measures to avoid affecting the normal use of the equipment.

c. Regularly inspect all connecting fasteners for looseness and thread slippage, and promptly adjust and replace them.

d. The motor must be regularly checked for loose and oxidized connection lines. If any of the above phenomena are found, they should be adjusted or replaced as soon as possible. The grounding wire must be reliably grounded.

Similar Product Recommend