-

E-mail

286450018@qq.com

-

Phone

18363648207

-

Address

Zhucheng City, Shandong Province

Product Categories

Zhucheng He'ao Machinery Technology Co., Ltd

Bean Bubble Cleaning Production Line

NegotiableUpdate on 01/08

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

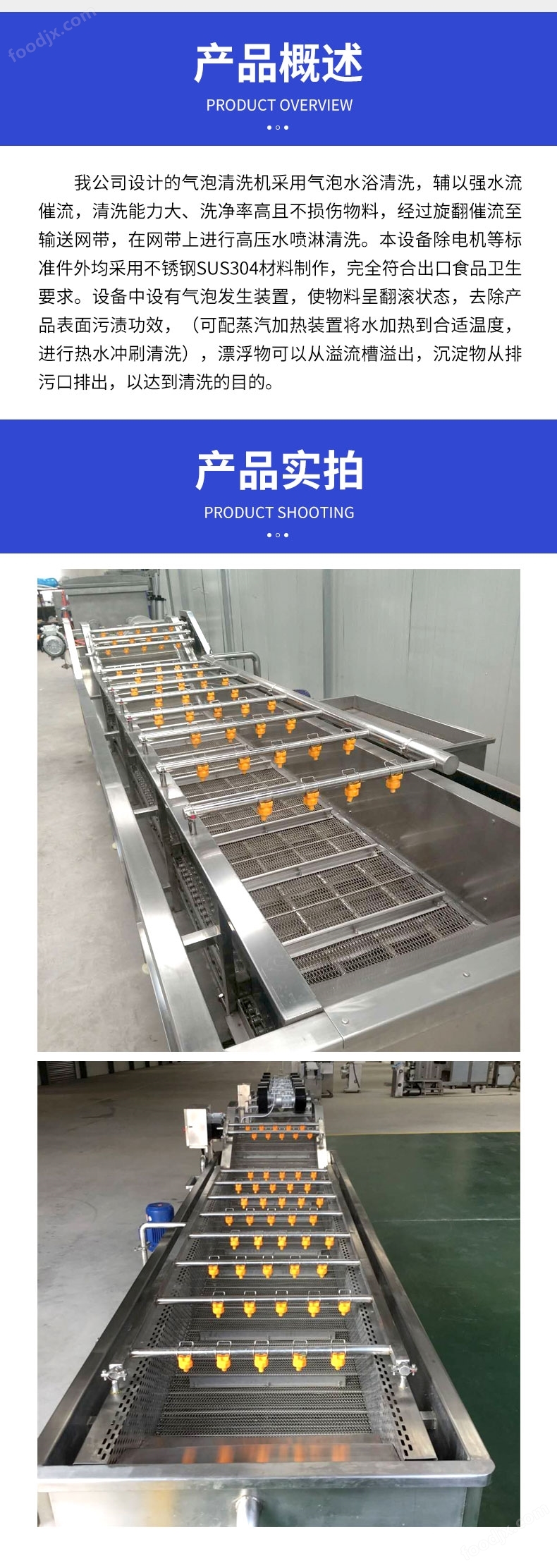

The bean bubble cleaning assembly line is a device that uses bubbles to clean vegetables and fruits. Its working principle is mainly through the circulation of water in the water tank of the equipment box through a high-pressure water pump. There is also a conveyor belt or chain plate driven by a conveyor motor inside the box. The vortex blower will input air into the bottom of the tank to form bubbles, which will drive the water flow to flip and roll the raw materials. After cleaning, the conveying device will lift the raw materials out of the tank.

Product Details

Bean Bubble Cleaning Production LineIt is an important product in jujube, vegetable, and aquatic production lines, mainly used for cleaning jujube, vegetable, and aquatic products. The principle of the bubble cleaner is mainly to inject an appropriate amount of water into the front part of the equipment box, and heat the water temperature through a heating tube. When the raw materials pass through the box, they will be rolled by the combination of the bubble cleaner and water, and continuously pushed forward with the mesh belt. When they come out of the water surface, there is a spray head for high-pressure flushing. It has the characteristics of high cleanliness, energy saving, water saving, stable and reliable equipment, and can maintain the original color. It is an ideal equipment for industries such as vegetables, food processing, and catering. Suitable for: Bubble vegetable cleaning machine for cleaning, soaking, sterilizing, disinfecting, and fixing granular, leaf shaped, and root and stem products such as leafy vegetables, edible fungi, fruits, aquatic products, and Chinese herbal medicines.

Bean Bubble Cleaning Production LineIt is a device that uses bubbles to clean vegetables and fruits. Its working principle is mainly through the circulation of water in the water tank of the device box through a high-pressure water pump. There is also a conveyor belt or chain plate driven by a conveyor motor inside the box. The vortex blower will input air into the bottom of the tank to form bubbles, which will drive the water flow to flip and roll the raw materials. After cleaning, the conveying device will lift the raw materials out of the tank. This type of machine generally determines the width of the equipment based on the width of the internal conveying device. The width of the conveying device is usually 600mm-1000mm, the length of the equipment is not less than 3000mm, the power is 2.7kw, and the production capacity is 3-4T/h. The bubble cleaner is mainly used for cleaning vegetables and fruits, which can clean the soil on the surface of vegetables and fruits, and also wash away the "pesticide residues" on the surface of vegetables and fruits.

Similar Product Recommend